Advanced Features for Concrete Batch Plants

High-production concrete plants need to find ways to keep up with processes and production, without losing out on quality, efficiency, and safety. Over time, equipment can become outdated while the operational needs of the facility continue to grow and evolve. Strategic upgrades to equipment within concrete batch plants can...

Tags: Concrete batching, management of concrete batch plant Read More- By : Jeph Novak

- concrete-batching

- No Comments on Enter Shutdown Season with a Plan

Enter Shutdown Season with a Plan

As the busiest parts of the construction season begin to wind down and demand for concrete production wanes, many concrete batch plants are preparing for annual shutdowns and maintenance. Getting ready for the quieter months is just as important as preparing for the busy season, as it can dictate...

Tags: Concrete batching, management of concrete batch plant, shutdowns Read MoreSafety Considerations for Concrete Batch Plants

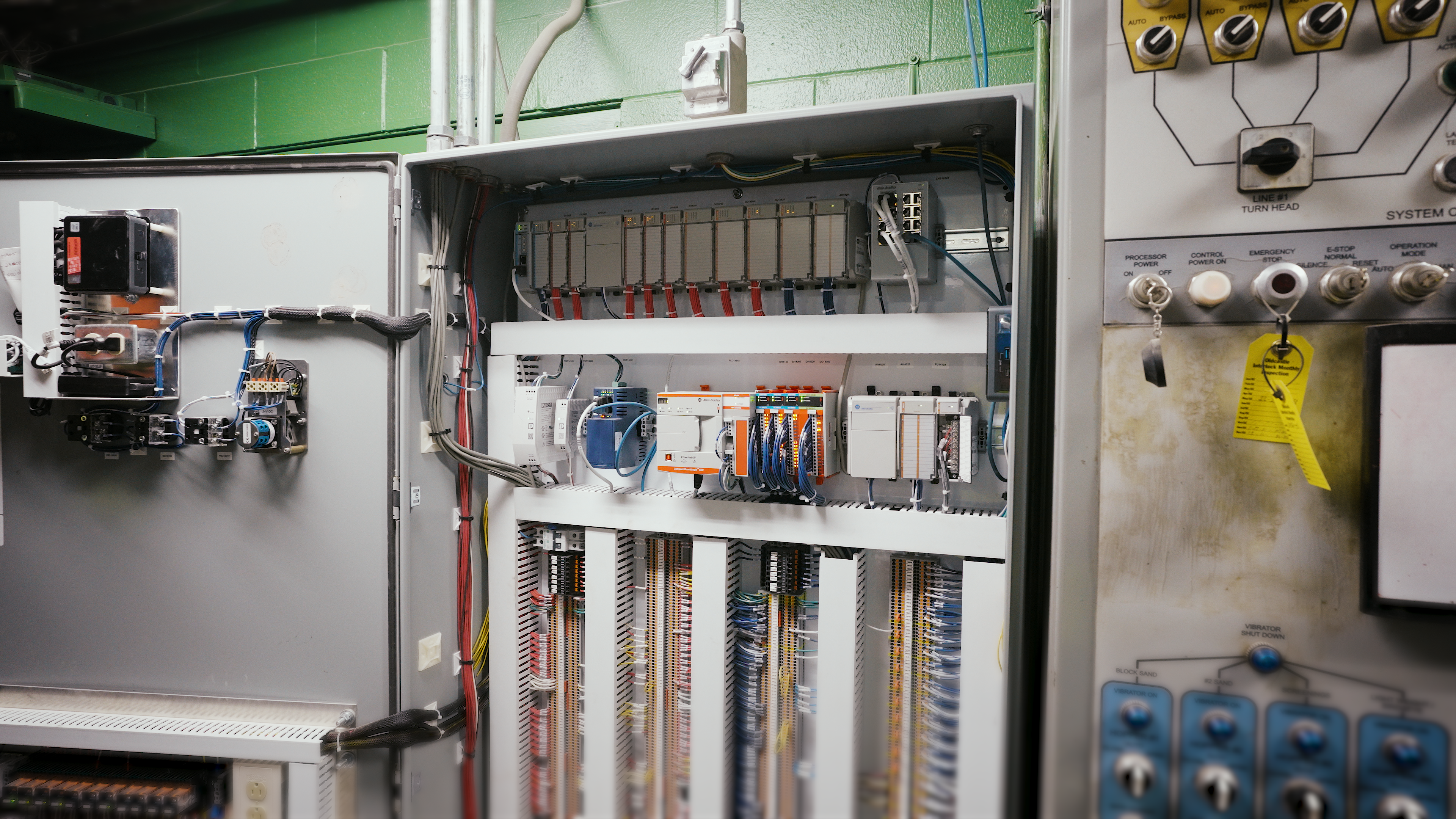

Maximizing safety in concrete production facilities is key for maintaining the wellbeing of personnel as well as optimization of the plant. During National Safety Month, take time to consider areas of your facility that can benefit from new safety measures – including electrical wiring, fire alarm & life safety...

Tags: Concrete batching, management of concrete batch plant, safety Read MoreProtect Your Plant with the Right Parts

Finding ways to get ahead of unexpected downtime can make a huge difference in the productivity and output of your concrete plant. Even with top equipment installed, the environment within a concrete batch plant can cause excessive wear and tear on the hardware. Dust, vibrations, and near-constant operations put...

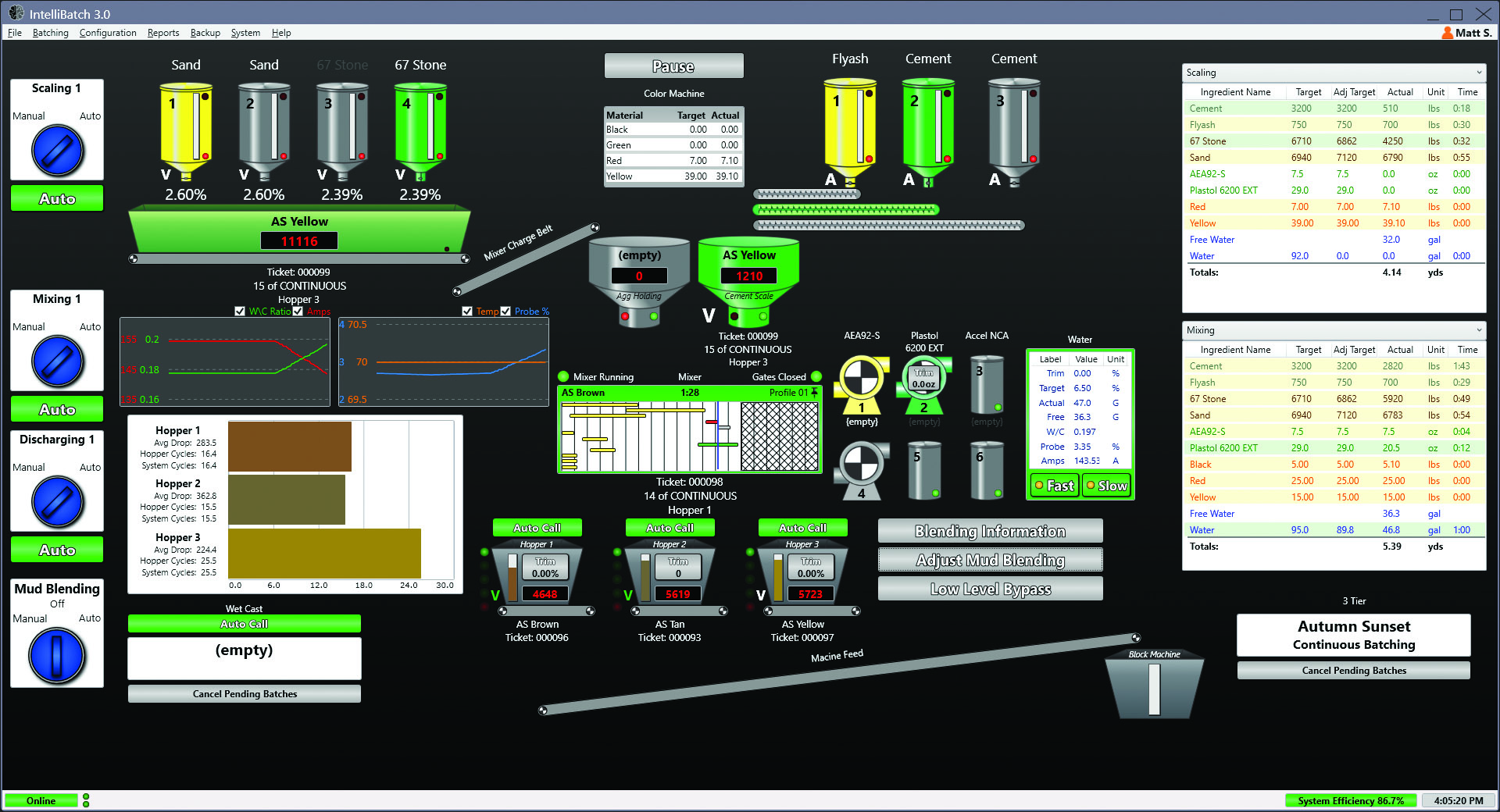

Tags: Concrete batching, management of concrete batch plant Read MoreThe Secret to Color Control in Your Pavers

Achieving consistent color in concrete pavers is key for a unified, high-quality product. Color control and consistency for concrete batch plant operators relies on key factors that make all the difference in producing blocks, pavers, and stepping stones. THE RIGHT INGREDIENTS Repeatability and consistency in color comes down to...

Tags: Concrete batching, concrete mix design, custom controls, management of concrete batch plant, Pavers Read More- By : Lexi Wahlstrom

- concrete-batching

- No Comments on WHAT ARE THE DIFFERENT TYPES OF BATCH PLANTS?

WHAT ARE THE DIFFERENT TYPES OF BATCH PLANTS?

Concrete batch plants are used to mix the ingredients of concrete, including water, cement, aggregates, and admixtures. Each type of plant has its own advantages and disadvantages. As your go-to resource in concrete batching, the IntelliBatch by Egan Company team has solutions for many batch plant needs. Dry Mix...

Tags: Concrete batching, management of concrete batch plant Read More- By : Lexi Wahlstrom

- concrete-batching

- No Comments on WHAT IS A BATCH PLANT OPERATION?

WHAT IS A BATCH PLANT OPERATION?

A batch plant is a facility that produces concrete by mixing cement, aggregates, water, and admixtures. The process of measuring, mixing, and delivering these materials to create concrete products is what encompasses a batch plant operation. These are the facilities in which the IntelliBatch team serves every day. A...

Tags: Concrete batching, management of concrete batch plant Read More