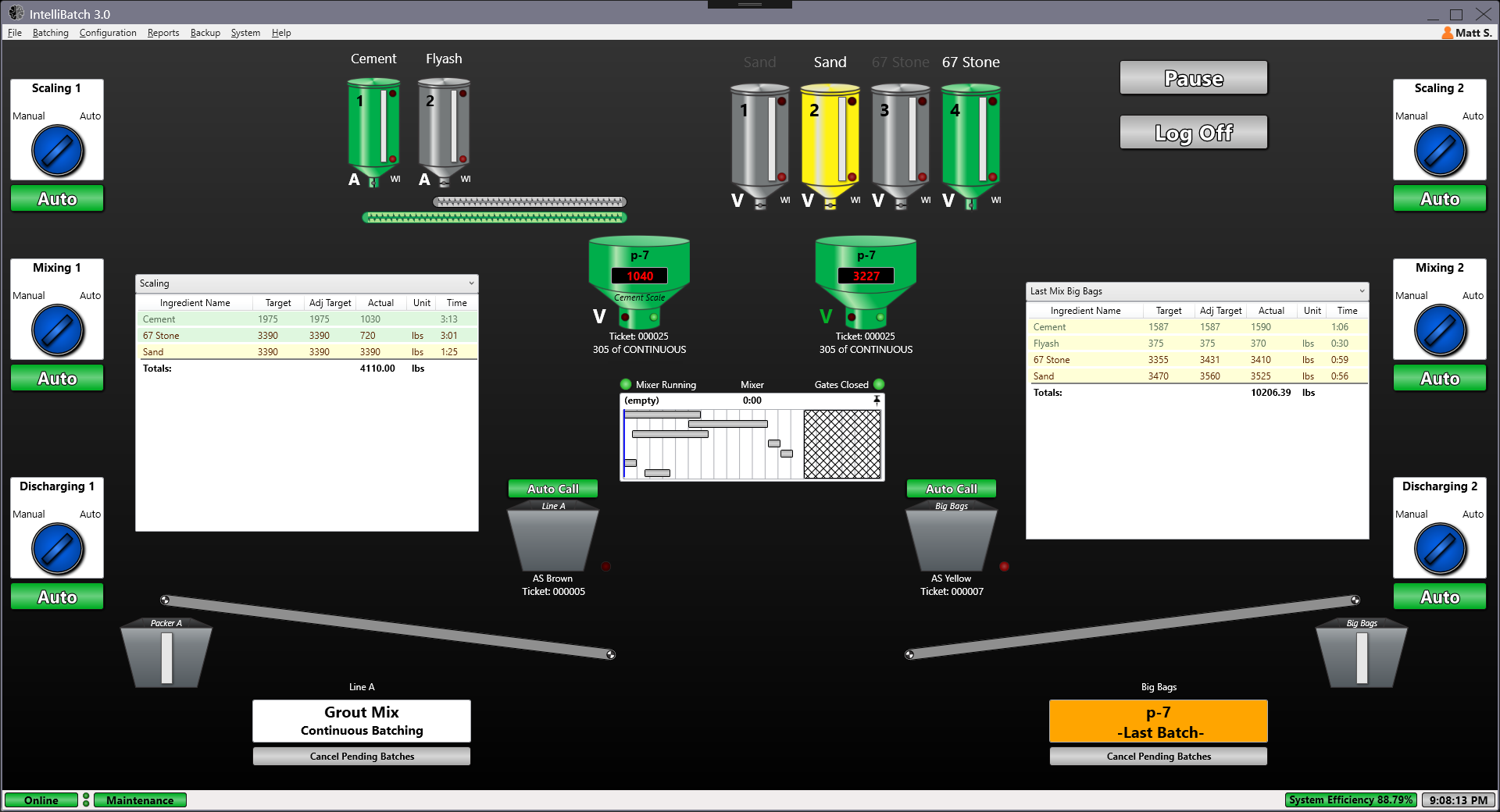

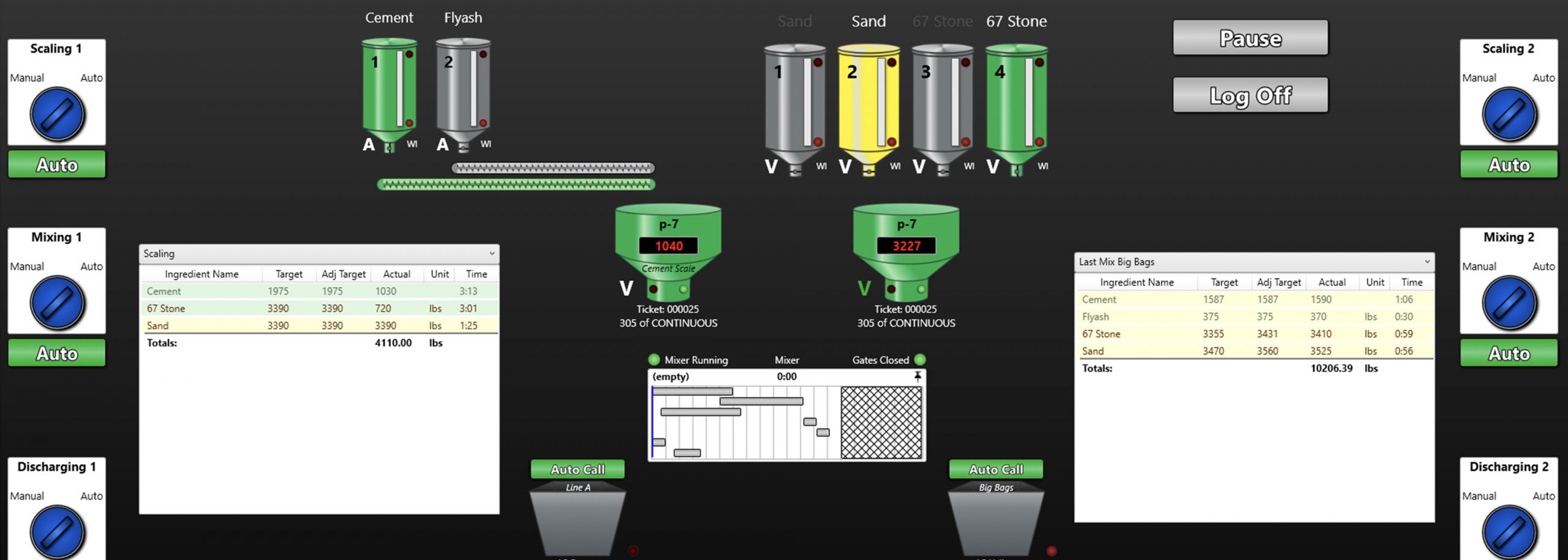

Leverage an intuitive user-interface and configurability that maximizes your plant’s productivity while increasing efficiency and quality.

Add on our optional Maintenance Reminder System to prevent unnecessary downtime and keep your plant equipment running in optimal condition.

For in-depth visuals such as dashboard displays, tracking insights, reporting, and other metrics, contact us.