Advanced Features for Concrete Batch Plants

High-production concrete plants need to find ways to keep up with processes and production, without losing out on quality, efficiency, and safety. Over time, equipment can become outdated while the operational needs of the facility continue to grow and evolve. Strategic upgrades to equipment within concrete batch plants can...

Read More- By : Jeph Novak

- concrete-batching

- No Comments on Enter Shutdown Season with a Plan

Enter Shutdown Season with a Plan

As the busiest parts of the construction season begin to wind down and demand for concrete production wanes, many concrete batch plants are preparing for annual shutdowns and maintenance. Getting ready for the quieter months is just as important as preparing for the busy season, as it can dictate...

Read More- By : Karley Burg

- concrete-batching

- No Comments on IntelliBatch: Behind the Controls of Smarter Concrete Production

IntelliBatch: Behind the Controls of Smarter Concrete Production

When it comes to building complex infrastructure, every detail matters—down to the precision of concrete batching. At Egan Company, IntelliBatch® is the software solution that keeps production running smoothly, consistently, and efficiently. Recently, we sat down with Jeremy Quam, Concrete Batch Operations Supervisor, and Matt Haan, Concrete Batch Project...

Read More- By : Jeph Novak

- concrete-batching

- No Comments on Preparing for Windows 10 End of Life

Preparing for Windows 10 End of Life

Microsoft has announced that starting October 14, 2025, Windows 10 will officially be obsolete for non-commercial users, removing support and updates for the operating system (OS). While many Microsoft users have fully transitioned Windows 11, commercial entities, such as IntelliBatch® by Egan Company, will continue to support the legacy...

Read MoreSafety Considerations for Concrete Batch Plants

Maximizing safety in concrete production facilities is key for maintaining the wellbeing of personnel as well as optimization of the plant. During National Safety Month, take time to consider areas of your facility that can benefit from new safety measures – including electrical wiring, fire alarm & life safety...

Read MoreProtect Your Production with Moisture Testing

Maintaining consistency in concrete batching requires precise control of many factors, including temperature, humidity, and aggregate mixtures within a batch plant environment. Moisture content is one of the biggest causes of poor quality of concrete, leading to ruined batches and unexpected costs. By monitoring the moisture levels within your...

Read MoreProtect Your Plant with the Right Parts

Finding ways to get ahead of unexpected downtime can make a huge difference in the productivity and output of your concrete plant. Even with top equipment installed, the environment within a concrete batch plant can cause excessive wear and tear on the hardware. Dust, vibrations, and near-constant operations put...

Read MoreThe Secret to Color Control in Your Pavers

Achieving consistent color in concrete pavers is key for a unified, high-quality product. Color control and consistency for concrete batch plant operators relies on key factors that make all the difference in producing blocks, pavers, and stepping stones. THE RIGHT INGREDIENTS Repeatability and consistency in color comes down to...

Read MoreSharing IntelliBatch at Industry Events

The beginning of the year brings a full schedule of events and trade shows across the concrete batching industry. Egan Company’s IntelliBatch® team started 2025 by attending two industry events in January and February: World of Concrete – Las Vegas, NV The Precast Show – Indianapolis, IN It was...

Read More- By : Jeph Novak

- concrete-batching

- No Comments on Is Your Hardware Due for an Upgrade?

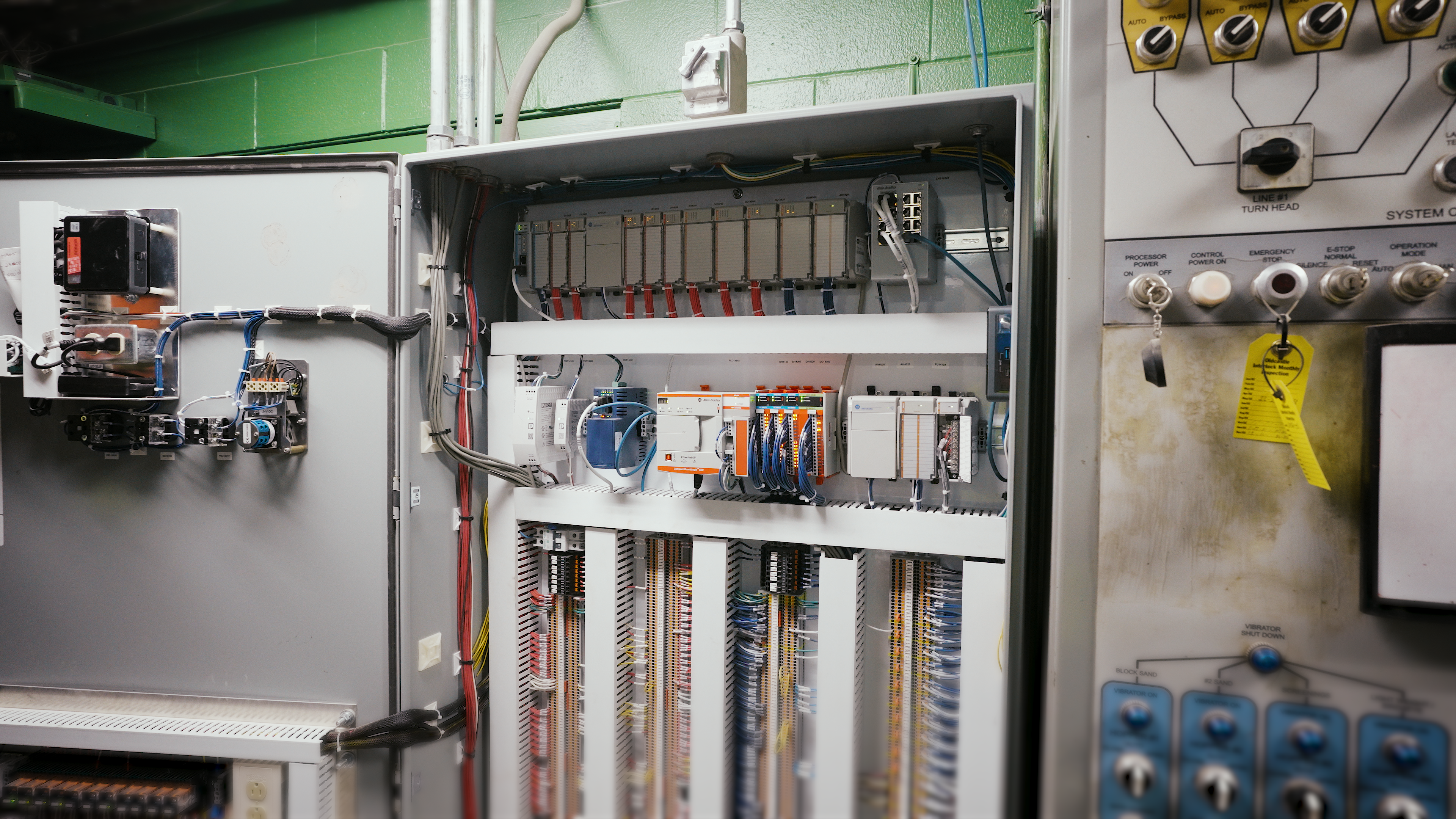

Is Your Hardware Due for an Upgrade?

Staying up to date with the latest hardware is essential for optimal performance within concrete plants. Outdated control hardware can hinder your operations, slow down processes, and lead to inefficiencies and potential security risks. Recognizing the signs that your hardware is due for an upgrade is the first step...

Read More- 1

- 2