Contact Us

Unlock your precast plant’s potential with IntelliBatch

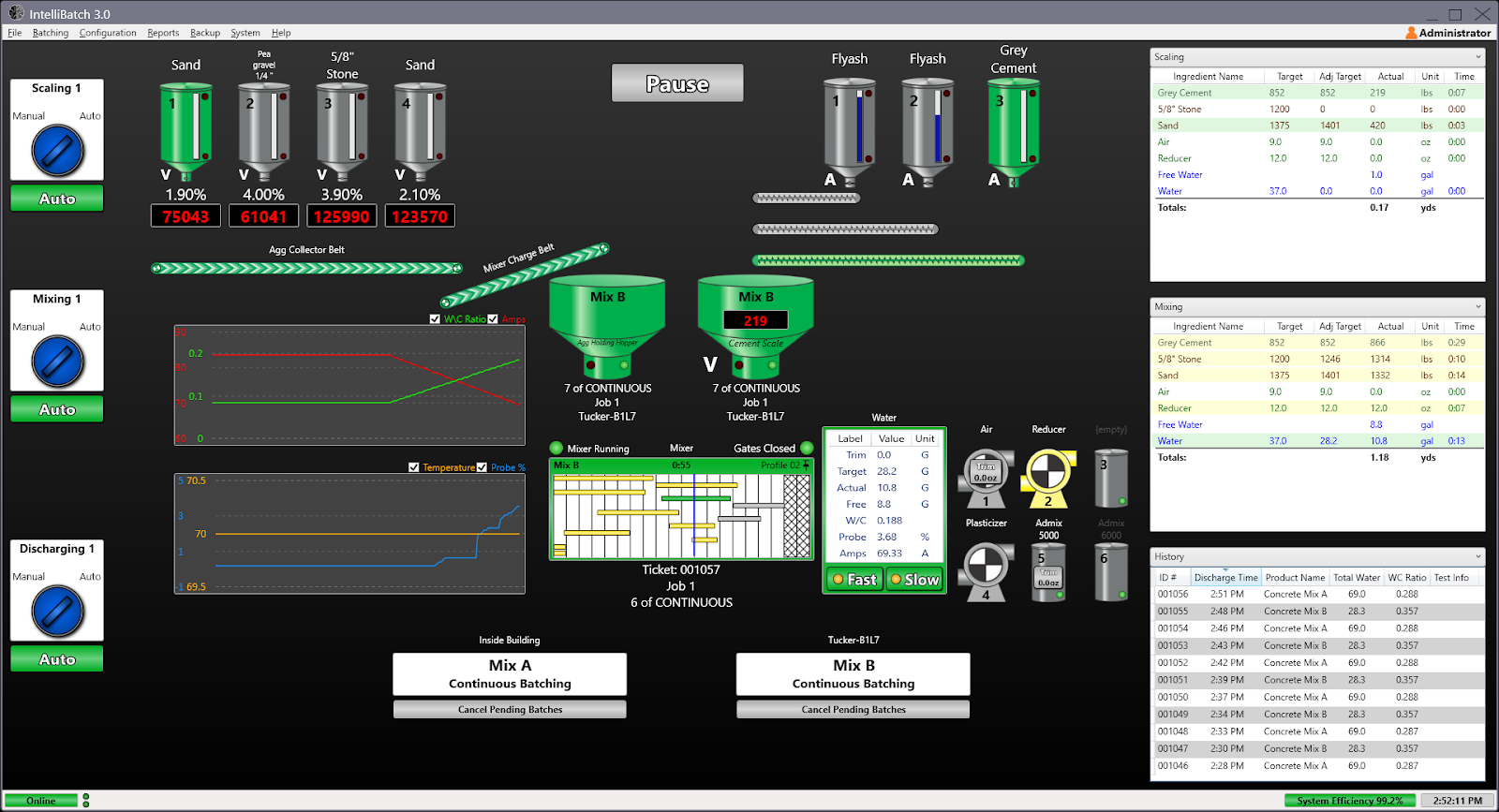

Leverage an intuitive user-interface and configurability that maximizes your plant’s productivity while increasing efficiency and quality.

We serve the following precast specialties: wetcast, drycast, self-consolidating concrete (SCC), architectural and structural wall panels, formed precast, pipe, pre-stressed, cast stone, stone veneer, and architectural precast.

Take advantage of our optional Maintenance Reminder System to prevent unnecessary downtime and keep your plant equipment running in optimal condition.

For in-depth visuals such as dashboard displays, tracking insights, reporting, and other metrics, contact us.

-

Operations made simpler with our intuitive graphical user interface

-

Clear and informative settings, alarms, and system events

-

Call a “mix design” with minimal clicks

-

Control the system from anywhere with tablets and remote operations stations

-

Adjust water and admix on the fly without any mix design modification

-

Switch bins while batching on the fly

-

Superior support and service with no required contract

-

Drive consistency with state-of-the-art mix design tools that allow full control with customizable water addition stages and parameters

-

Intelligent weigh-up assistant delivers fast and accurate material dispensing

-

Enhanced security features that allow only authorized personnel to edit mix design and make system changes

-

Effective Advanced Integrated Moisture compensation – you’ll know where your batch water is coming from

-

Integrated calibration tools for scales and moisture sensors

-

Audit system changes with system revision

-

Compliant with PCI, NPCA, and state DOT requirements

-

Log QC tests to individual batch tickets with Integrated SCC and Slump test entry

-

Web-based quality reports including: production, inventory, material usage, and variances

-

Custom reports also available

-

Ensure proper routine maintenance with our Maintenance Reminder System

-

Easy to understand alarms with clear resolution descriptions

-

Alarm and event notification to key personnel via text and/or email alerts

-

Intuitive on-screen or push button manual control of any device

-

Web-based quality reports including: individual material weigh-up times, material and mix moistures, and bin levels

-

Custom reports also available

-

Easily diagnose field devices with a built-in I/O monitor

-

Optimize plant production and efficiency through maximizing your equipment utilization

-

High availability and up-time with multiple stations for local control

-

Compliant with PCI, NPCA, and state DOT requirements

-

Non-proprietary industrial hardware

-

Communicate with Enterprise systems via SQL integration

-

Deliver accountability through system activity and change tracking

-

OEE reporting with optimal system efficiency monitoring

-

Reliable 24/7/365 support